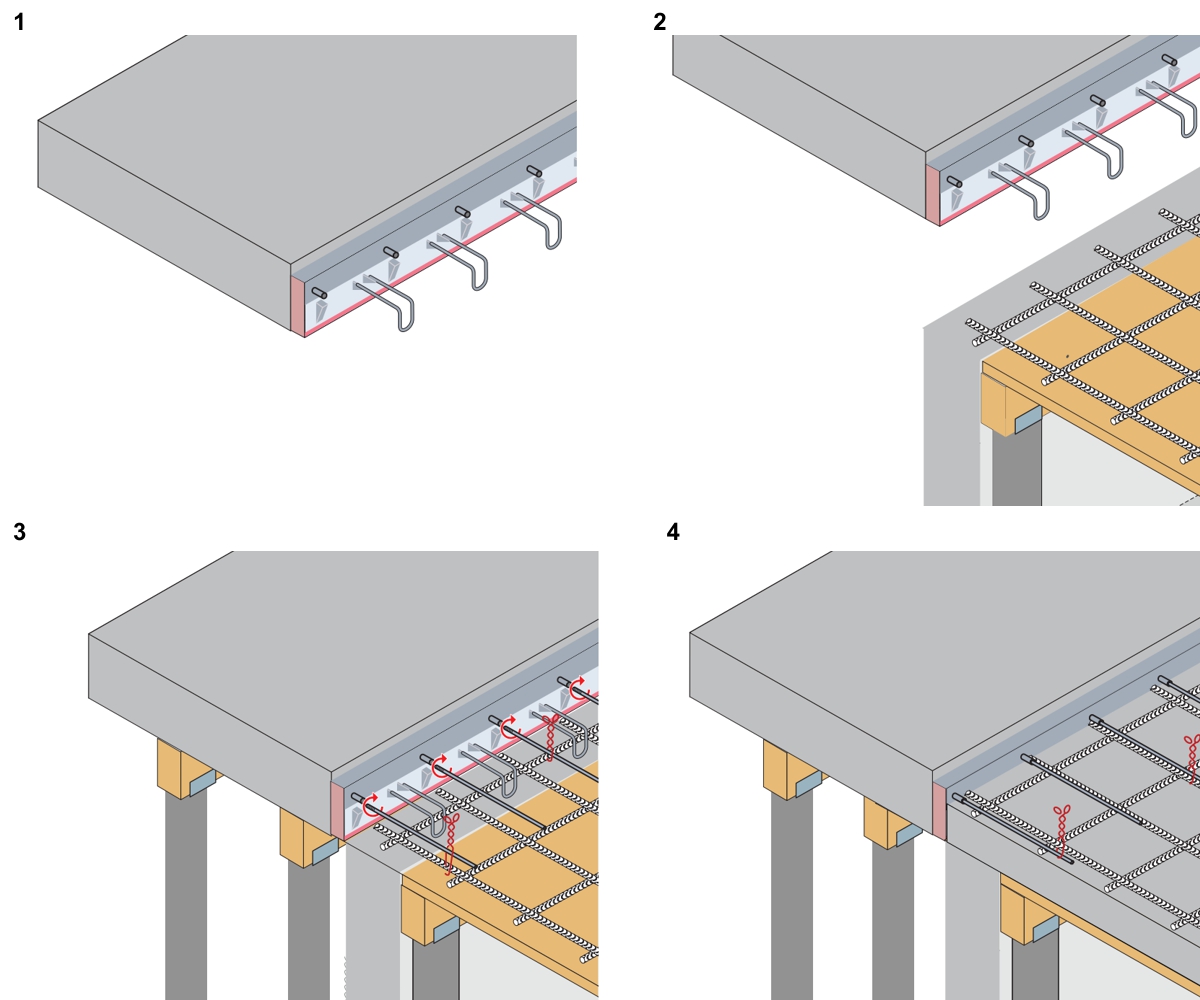

Thermotec E connector

Thermotec E connectors can withstand higher shear forces compared to standard A connectors. The connector only transfers shear forces and bending moments in one direction.

Its main advantages are:

Load capacities given in tables have been prepared for typical cases and the reinforcement ratio at the level of 0.5% and 1%. Load capacities for higher ratios of the reinforcement, elements close to edges and connector systems can be determined according to the procedure in the last chapter of the catalogue Thermotec E balcony connectors allow the transfer of transverse forces and bending moments acting in one direction without the need to meet the minimum ratio of the moment and the shear force.

Characteristics of the Thermotec E connector: :

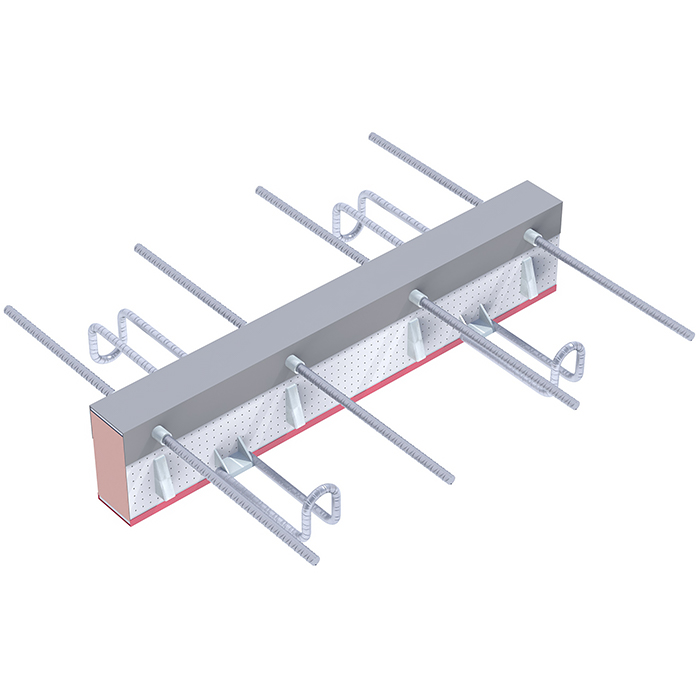

Thermotec E designation scheme

Thermotec E connector dimensions

| Connector type | Number of sleeves | Numbr of bearings | Number of hangers | c | L | H | Lbd |

| mm | mm | mm | mm | ||||

| 4x14-1-1000 | 4 | 4 | 1 | 30-50 | 1000 | 160-250 | The anchorage/overlap length is always selected individually for Thermotec E1 connectors |

| 4x14-2-1000 | 4 | 4 | 2 | 1000 | |||

| 6x14-3-500 | 6 | 6 | 3 | 1000 | |||

| 2x14-1-500 | 2 | 2 | 1 | 500 | |||

| 4x14-2-500 | 4 | 4 | 2 | 500 | |||

| 4x14-3-500 | 4 | 4 | 3 | 500 | |||

| 2x14-1-250 | 2 | 2 | 1 | 250 |

Lambda equivalent table of Thermotec E connectors

| H | 160 | 170 | 180 | 190 | 200 | 210 | 220 | 230 | 240 | 250 | ||||||||||

| Type | λeq | Req | λeq | Req | λeq | Req | λeq | Req | λeq | Req | λeq | Req | λeq | Req | λeq | Req | λeq | Req | λeq | Req |

| 4x14-1-1000 | 0,32 | 0,25 | 0,31 | 0,26 | 0,29 | 0,27 | 0,28 | 0,29 | 0,26 | 0,30 | 0,25 | 0,32 | 0,24 | 0,33 | 0,23 | 0,34 | 0,22 | 0,36 | 0,22 | 0,37 |

| 4x14-2-1000 | 0,40 | 0,20 | 0,38 | 0,21 | 0,36 | 0,22 | 0,34 | 0,23 | 0,32 | 0,25 | 0,31 | 0,26 | 0,30 | 0,27 | 0,29 | 0,28 | 0,27 | 0,29 | 0,26 | 0,30 |

| 6x14-3-1000 | 0,48 | 0,17 | 0,45 | 0,18 | 0,43 | 0,19 | 0,40 | 0,20 | 0,39 | 0,21 | 0,37 | 0,22 | 0,35 | 0,23 | 0,34 | 0,24 | 0,32 | 0,25 | 0,31 | 0,26 |

| 2x14-2-1000 | 0,55 | 0,14 | 0,52 | 0,15 | 0,49 | 0,16 | 0,47 | 0,17 | 0,45 | 0,18 | 0,43 | 0,19 | 0,41 | 0,20 | 0,39 | 0,20 | 0,38 | 0,21 | 0,36 | 0,22 |

| 4x14-2-1000 | 0,63 | 0,13 | 0,59 | 0,13 | 0,56 | 0,14 | 0,53 | 0,15 | 0,51 | 0,16 | 0,48 | 0,17 | 0,46 | 0,17 | 0,44 | 0,18 | 0,43 | 0,19 | 0,41 | 0,20 |

| 4x14-3-500 | 0,32 | 0,25 | 0,31 | 0,26 | 0,29 | 0,27 | 0,28 | 0,29 | 0,26 | 0,30 | 0,25 | 0,32 | 0,24 | 0,33 | 0,23 | 0,34 | 0,22 | 0,36 | 0,22 | 0,37 |

| 2x14-1-250 | 0,48 | 0,17 | 0,45 | 0,18 | 0,43 | 0,19 | 0,40 | 0,20 | 0,39 | 0,21 | 0,37 | 0,22 | 0,35 | 0,23 | 0,34 | 0,24 | 0,32 | 0,25 | 0,31 | 0,26 |

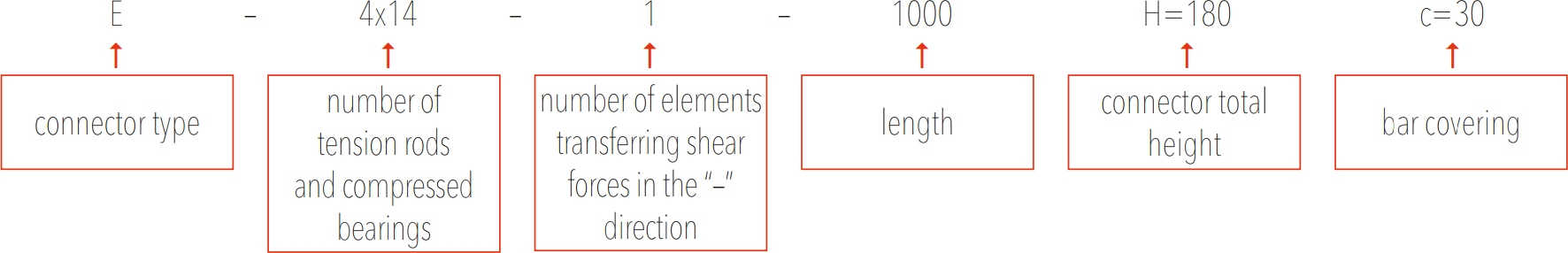

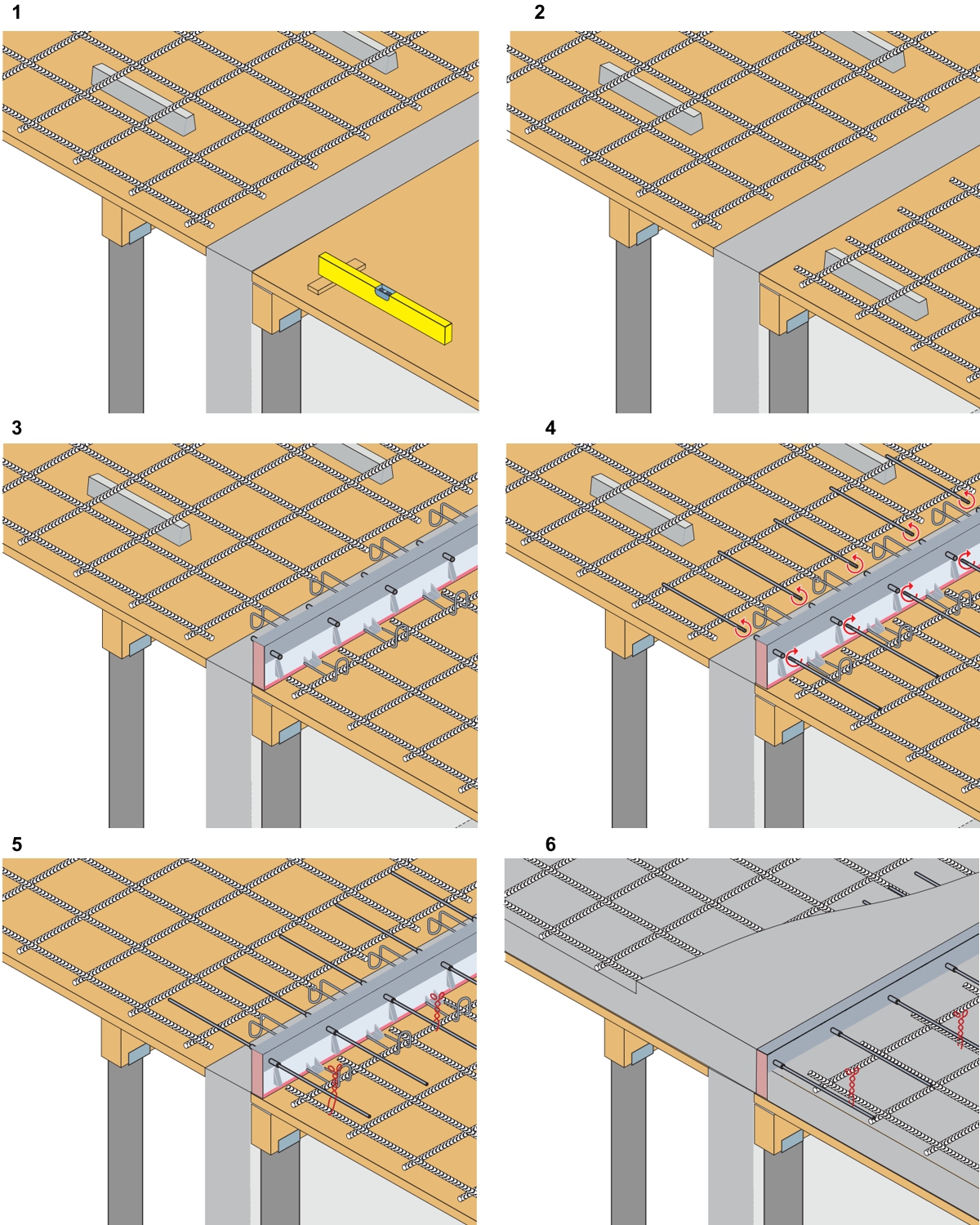

Assembly instructions - Thermotec E

Installation of balcony connectors when balconies are made on site.

Installation of balcony connectors when balconies are made in prefabrication workshop

Notes:

- strictly observe the assembly direction marked on the connector.

- the presented diagram is a recommendation that draws attention to the most important aspects of connector assembly. Specific cases and solutions used on the construction site may need to be completed.

The contractor is responsible for the correct installation method. In order to clarify any questions or doubts, please contact the EXTREA technical department.