Thermotec is a safe and easy to install method of connecting the ceiling with the balcony slab. Its main advantages are:

Thermotec A balcony connectors enable the transfer of transverse forces and bending moments acting in the connection.

Characteristics of the Thermotec A connector:

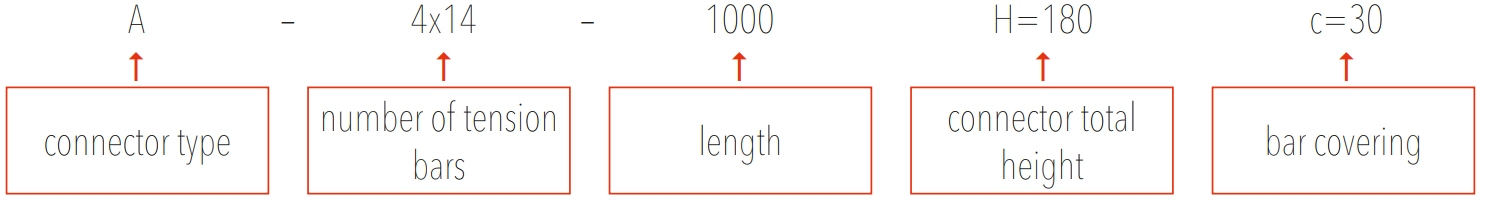

Thermotec A - designation scheme

For the correct operation of Thermotec A balcony connectors, the minimum ratio of the moment and the shear force specified in the table is required

| convering c =30 mm | ||||||||||

| h [mm] | 160 | 170 | 180 | 190 | 200 | 210 | 220 | 230 | 240 | 250 |

| emin [m] | 0,13 | 0,15 | 0,17 | 0,19 | 0,21 | 0,24 | 0,26 | 0,26 | 0,28 | 0,30 |

| convering c =35 mm | ||||||||||

| h [mm] | 165 | 170 | 180 | 190 | 200 | 210 | 220 | 230 | 240 | 250 |

| emin [m] | 0,13 | 0,14 | 0,16 | 0,18 | 0,20 | 0,21 | 0,23 | 0,25 | 0,26 | 0,29 |

| convering c =50 mm | ||||||||||

| h [mm] | - | - | 180 | 190 | 200 | 210 | 220 | 230 | 240 | 250 |

| emin [m] | - | - | 0,13 | 0,15 | 0,17 | 0,19 | 0,21 | 0,22 | 0,24 | 0,26 |

Connector dimension

| Connector type | Number of sleeves | Number of bars | Number of bearings | c | L | H | Lbd |

| mm | mm | mm | mm | ||||

| 4x14-1000 | 4 | 8 | 4 | 30-50 | 1000 | 160-250 | As a standard, 75 cm for a straight bar. The anchorage/overlap length is a always selected individually for Thermotec A1 connectors. |

| 5x14-1000 | 5 | 10 | 5 | 1000 | |||

| 6x14-1000 | 6 | 12 | 6 | 1000 | |||

| 7x14-1000 | 7 | 14 | 7 | 1000 | |||

| 8x14-1000 | 8 | 16 | 8 | 1000 | |||

| 2x14-500 | 2 | 4 | 2 | 500 | |||

| 3x14-500 | 3 | 6 | 3 | 500 | |||

| 4x14-500 | 4 | 8 | 4 | 500 | |||

| 2x14-250 | 2 | 4 | 2 | 250 |

Lambda equivalent table of Thermotec A connectors

| Connector height | 160 | 170 | 180 | 190 | 200 | 210 | 220 | 230 | 240 | 250 | ||||||||||

| Typ | λeq | Req | λeq | Req | λeq | Req | λeq | Req | λeq | Req | λeq | Req | λeq | Req | λeq | Req | λeq | Req | λeq | Req |

| 4x14-1000 | 0,32 | 0,25 | 0,31 | 0,26 | 0,29 | 0,27 | 0,28 | 0,29 | 0,26 | 0,30 | 0,25 | 0,32 | 0,24 | 0,33 | 0,23 | 0,34 | 0,22 | 0,36 | 0,22 | 0,37 |

| 5x14-1000 | 0,40 | 0,20 | 0,38 | 0,21 | 0,36 | 0,22 | 0,34 | 0,23 | 0,32 | 0,25 | 0,31 | 0,26 | 0,30 | 0,27 | 0,29 | 0,28 | 0,27 | 0,29 | 0,26 | 0,30 |

| 6x14-1000 | 0,48 | 0,17 | 0,45 | 0,18 | 0,43 | 0,19 | 0,40 | 0,20 | 0,39 | 0,21 | 0,37 | 0,22 | 0,35 | 0,23 | 0,34 | 0,24 | 0,32 | 0,25 | 0,31 | 0,26 |

| 7x14-1000 | 0,55 | 0,14 | 0,52 | 0,15 | 0,49 | 0,16 | 0,47 | 0,17 | 0,45 | 0,18 | 0,43 | 0,19 | 0,41 | 0,20 | 0,39 | 0,20 | 0,38 | 0,21 | 0,36 | 0,22 |

| 8x14-1000 | 0,63 | 0,13 | 0,59 | 0,13 | 0,56 | 0,14 | 0,53 | 0,15 | 0,51 | 0,16 | 0,48 | 0,17 | 0,46 | 0,17 | 0,44 | 0,18 | 0,43 | 0,19 | 0,41 | 0,20 |

| 2x14-500 | 0,32 | 0,25 | 0,31 | 0,26 | 0,29 | 0,27 | 0,28 | 0,29 | 0,26 | 0,30 | 0,25 | 0,32 | 0,24 | 0,33 | 0,23 | 0,34 | 0,22 | 0,36 | 0,22 | 0,37 |

| 3x14-500 | 0,48 | 0,17 | 0,45 | 0,18 | 0,43 | 0,19 | 0,40 | 0,20 | 0,39 | 0,21 | 0,37 | 0,22 | 0,35 | 0,23 | 0,34 | 0,24 | 0,32 | 0,25 | 0,31 | 0,26 |

| 4x14-500 | 0,63 | 0,13 | 0,59 | 0,13 | 0,56 | 0,14 | 0,53 | 0,15 | 0,51 | 0,16 | 0,48 | 0,17 | 0,46 | 0,17 | 0,44 | 0,18 | 0,43 | 0,19 | 0,41 | 0,20 |

| 2x14-250 | 0,63 | 0,13 | 0,59 | 0,13 | 0,56 | 0,14 | 0,53 | 0,15 | 0,51 | 0,16 | 0,48 | 0,17 | 0,46 | 0,17 | 0,44 | 0,18 | 0,43 | 0,19 | 0,41 | 0,20 |

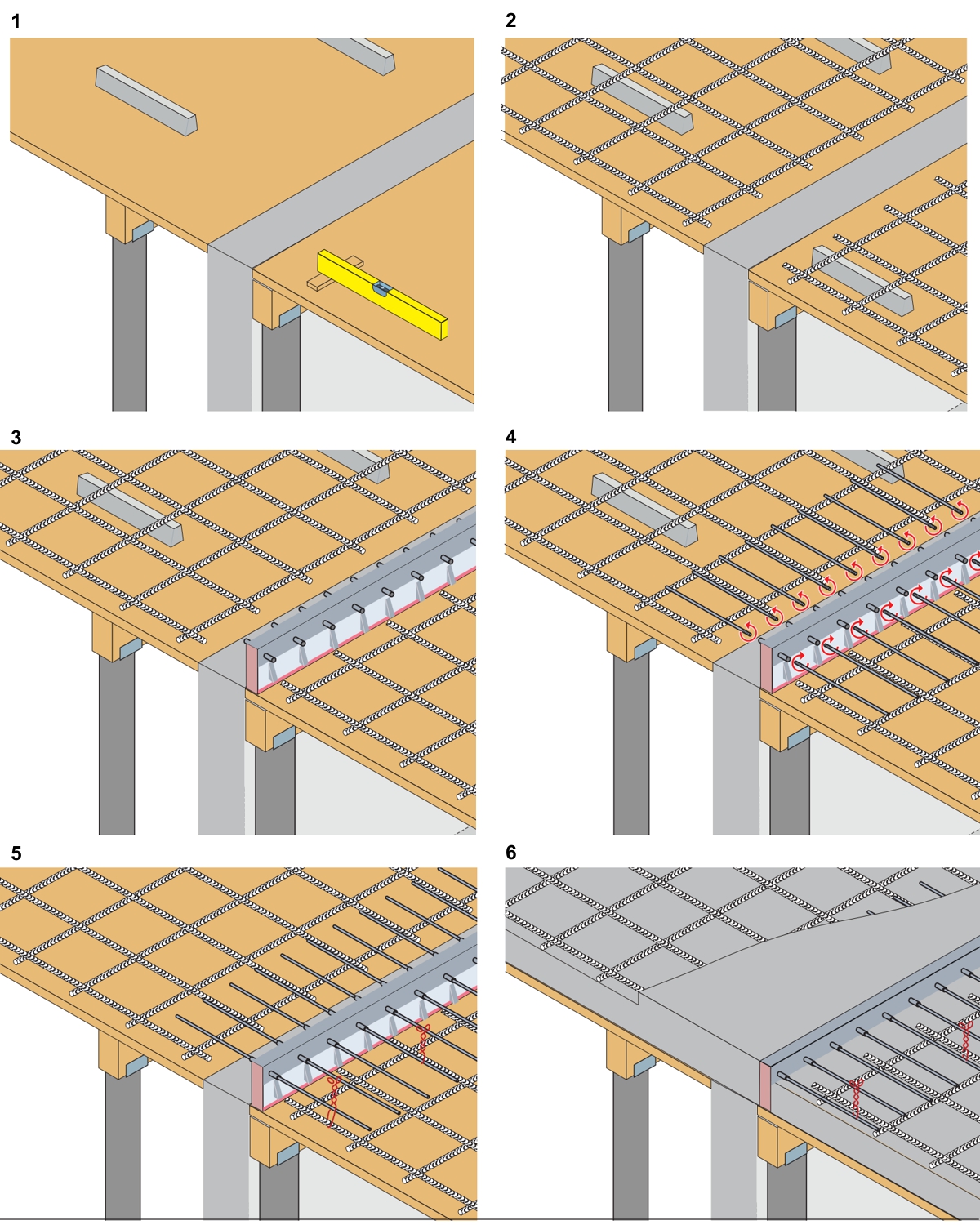

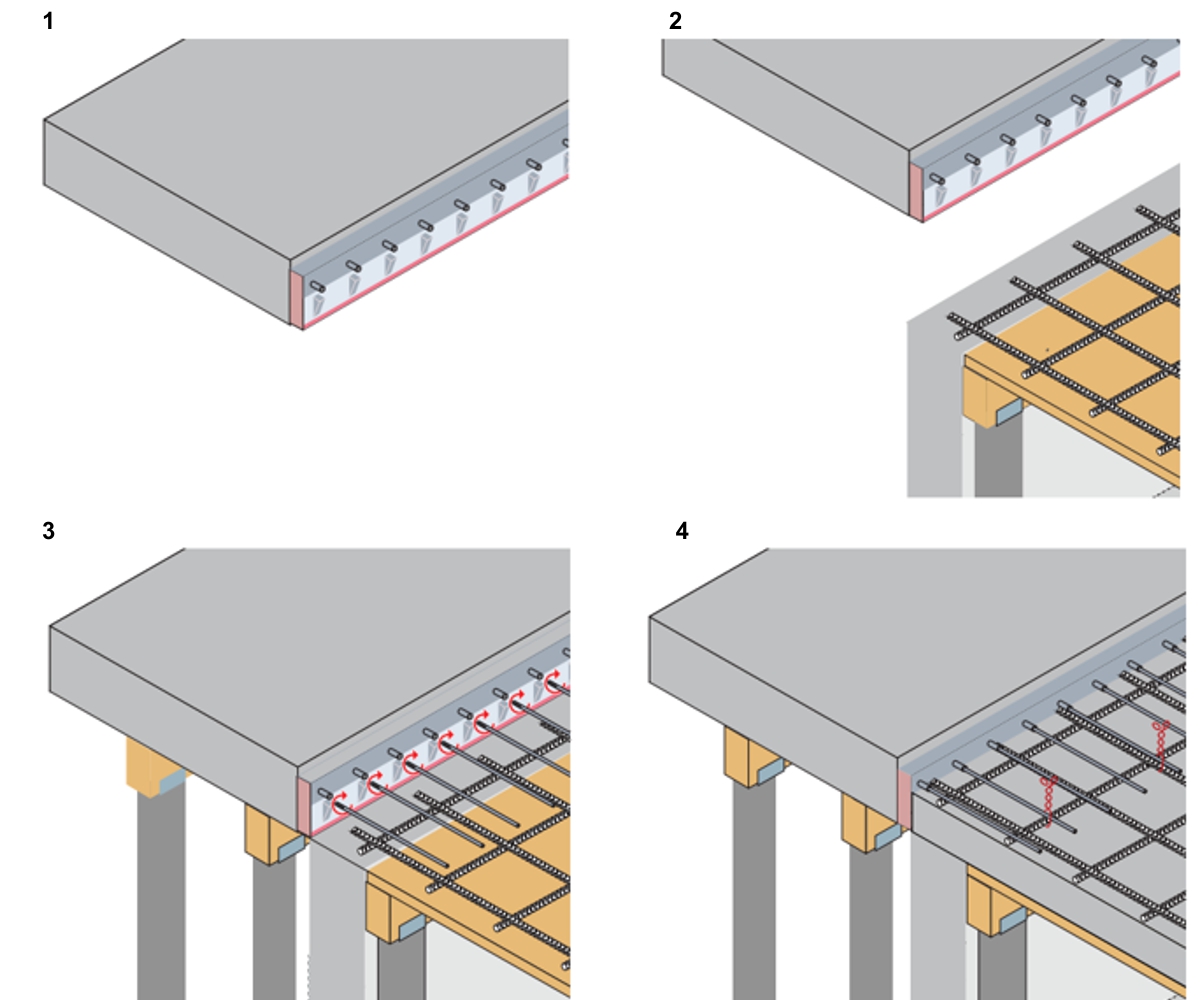

Assembly instructions- Thermotec A

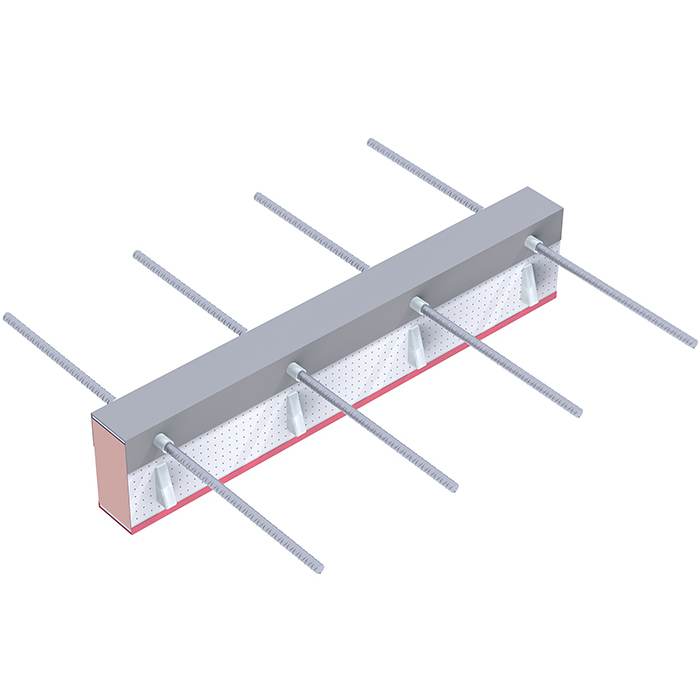

Installation of balcony connectors when balconies are made on site.

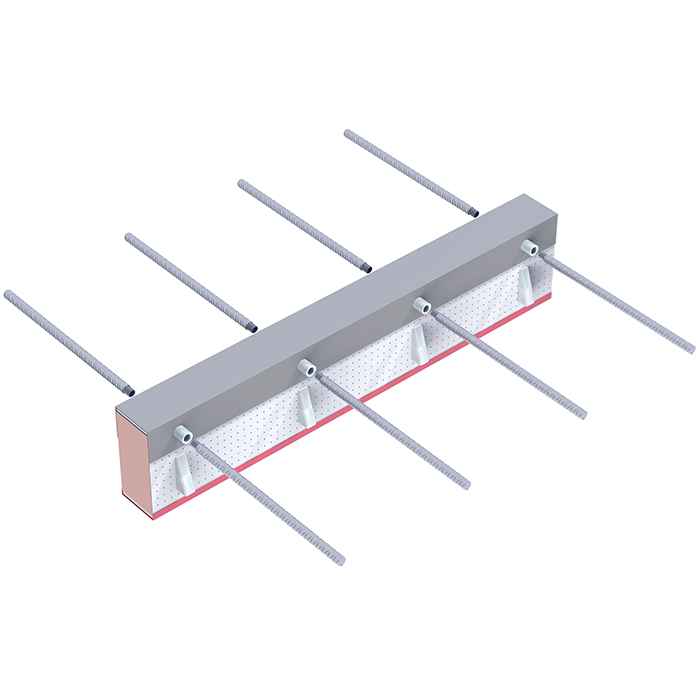

Installation of balcony connectors when balconies are made in prefabrication workshop

Notes:

- strictly observe the assembly direction marked on the connector,

- the presented diagram is a recommendation that draws attention to the most important aspects of connector assembly.

Specific cases and solutions used on the construction site may need to be completed. The contractor is responsible for the correct installation method. In order to clarify any questions or doubts, please contact the EXTREA technical department.

Thermotec A – retrofitting

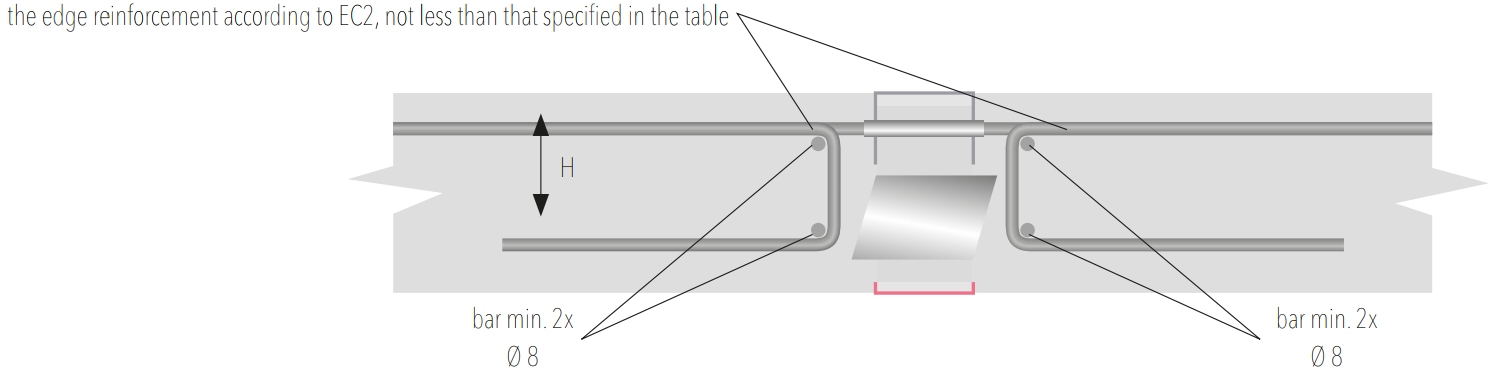

Tensile reinforcement section of connectors (in cm2/m)

| Connector | Tensile reinforcement | Minimum reinforcement of the edge of the balcony/slab |

| cm2/m | ||

| A-4x14-1000 | 6,16 | Φ 8 every 25 |

| A-5x14-1000 | 7,70 | Φ 8 every 20 |

| A-6x14-1000 | 9,24 | Φ 8 every 15 |

| A-7x14-1000 | 10,78 | Φ 8 every 13 |

| A-8x14-1000 | 12,32 | Φ 8 every 12,5 |

| A-2x14-500 | 6,16 | Φ 8 every 25 |

| A-3x14-500 | 9,24 | Φ 8 every 15 |

| A-4x14-500 | 12,32 | Φ 8 every 12,5 |

| A-2x14-250 | 12,32 | Φ 8 every 12,5 |