Product description

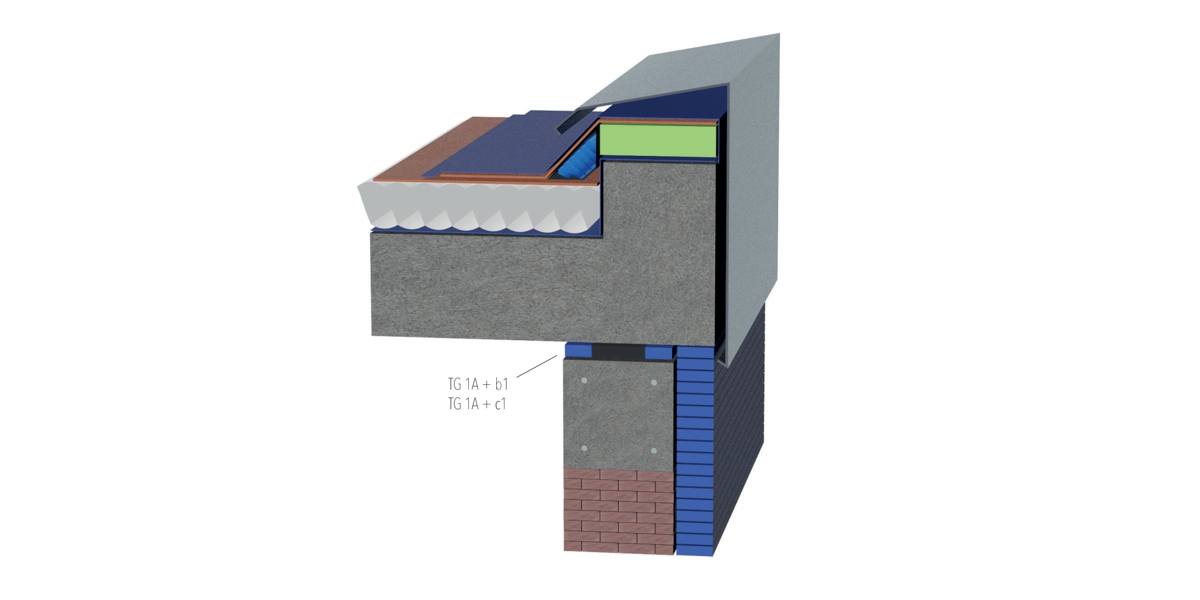

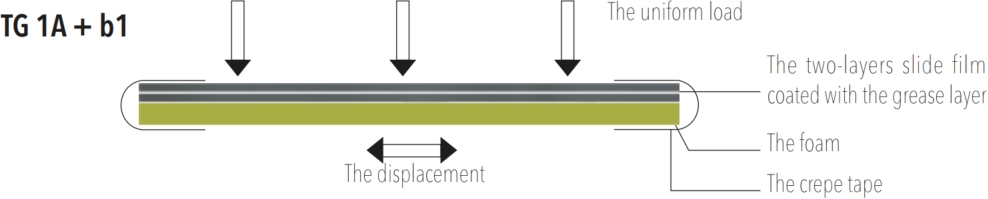

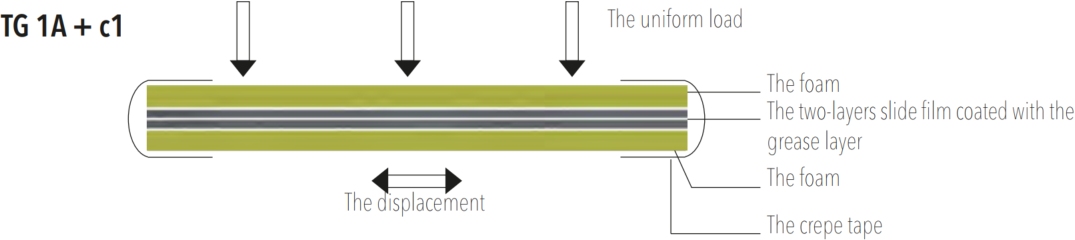

TG 1 A slide films with the inspection certificate are intended for roof structures with small spans. The use of the slide film reduces forces caused by shrinkage and creep of structural elements and those caused by the influence of the temperature. It prevents cracking walls caused by shear loads. In the case of roofs with longer spans, tape washers with the elastomeric core should be used to concentrate the load.

Application:

The task of the foam coating is to smooth out slight unevenness and roughness of the supporting surface.

The task of the foam coating is to smooth out slight unevenness and roughness of the supporting surface.

| Type | The maximum stress |

The friction coefficient |

The temperature |

The thickness |

| N/mm2 | °C | mm | ||

| The side film TG 1 A + b1 | 1 | 0,05 do 0,10 | 23 | 3 |

| The slide film TG 1 A + c1 | 1 | 0,05 do 0,10 | 23 | 5 |

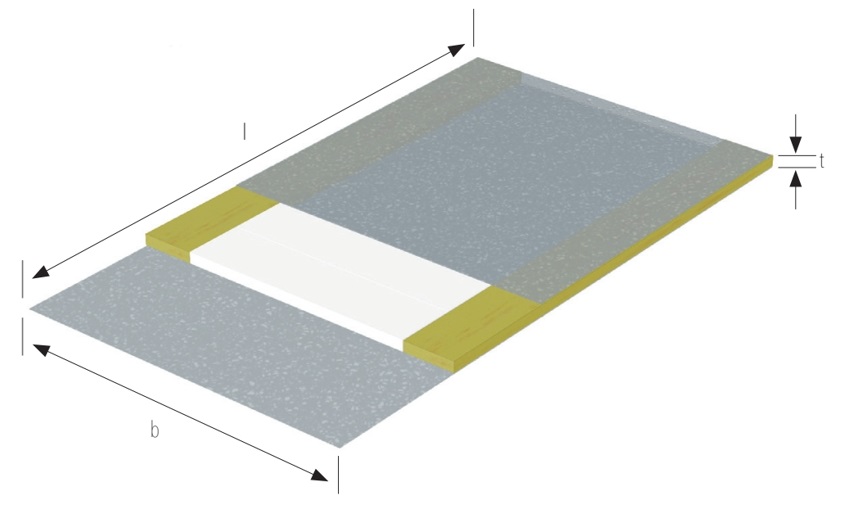

The standard length: 1.5 m

The width: all wall widths used.

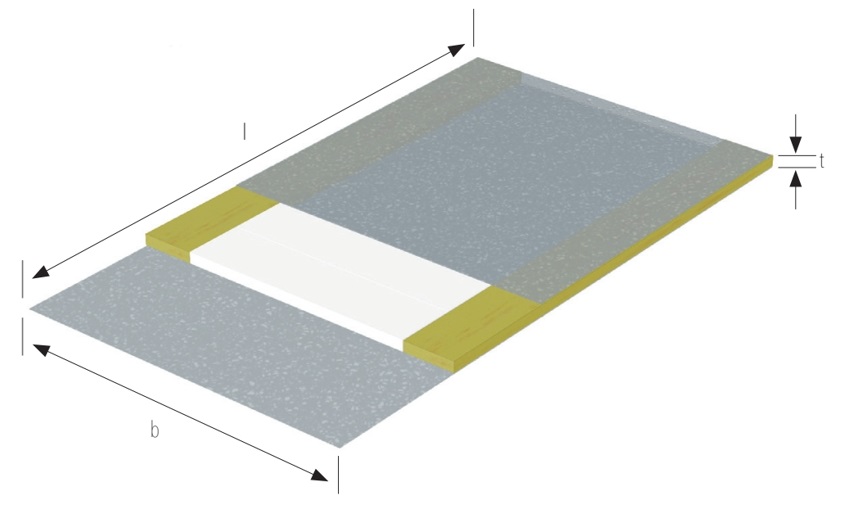

Specification: t x b x l mm RUBA type TG1A+…

t - the slide film thickness, mm,

b - the slide film width, mm,

l - the slide film length, mm.

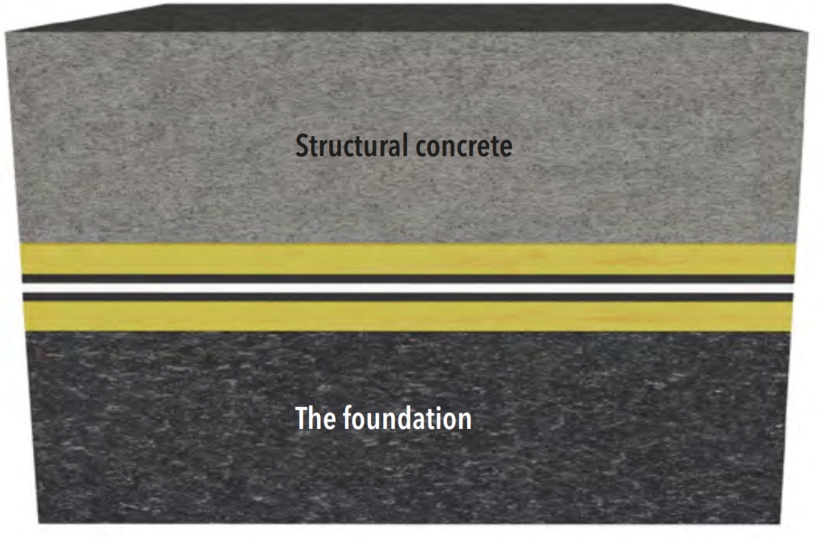

Bearing the foundation

TG 1 A type slide films laminated with elastomer are designed to separate elements subjected to loads up to 3 N/mm2, e.g. within the foundation, as well as to limit forces arising from temperature changes in components or structure settlement. With the pressure up to 10 N/mm2, the TG5POM film should be used.

Laminowanie warstwą elastomerową jest wymagane w celu wyrównania istniejących nierówności i nieznacznych odchyłek równoległości powierzchni przylegania.

| Type | The maxiumum stress |

The friction coefficient |

Temperature | Thickness |

| N/mm2 | °C | mm | ||

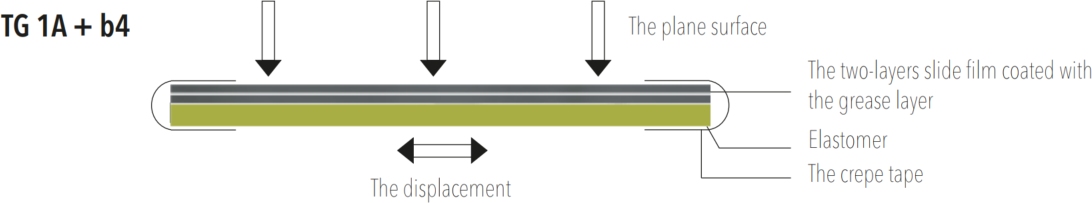

| The slide film TG 1 A + b4 | 3 | 0,05 d0 0,10 | 23 | 3 |

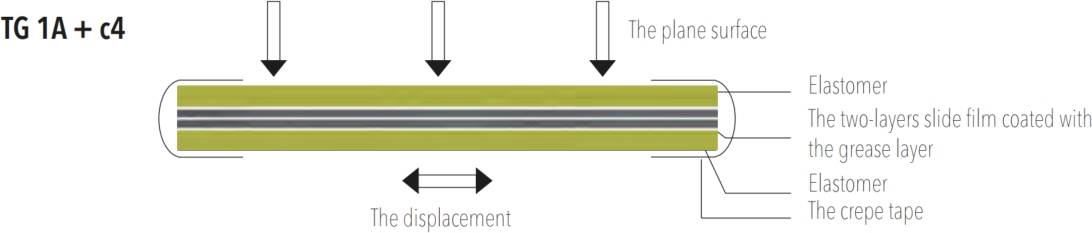

| Th slide film TG 1 A + c4 | 3 | 0,05 d0 0,10 | 23 | 5 |

Specification: t x b x l mm RUBA type TG1A+ c3

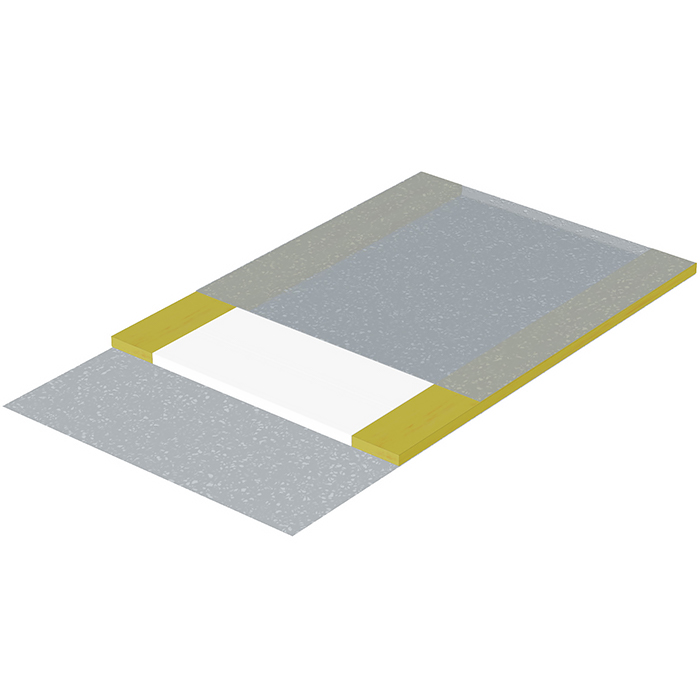

A slide film used on large surfaces

A slide film used on large surfaces

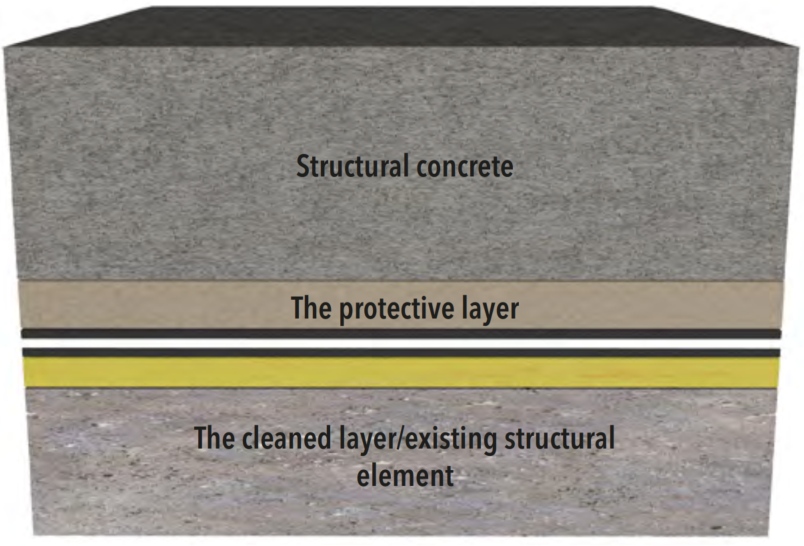

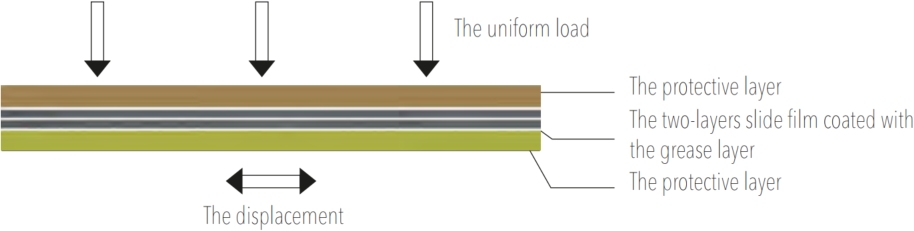

TG 1 A type slide films are designed to separate construction elements with large surfaces in order to reduce forces caused by changes in dimensions of elements, which may occur as a result of the temperature, creep or shrinkage, e.g. between the construction element and the substrate or between the existing and new element (swimming pools, reservoirs, ice rinks) or in the case of renovation of existing decking on existing structures.

In order to protect the slide film against mechanical damage and to even out the remaining unevenness on the contact surface, it is recommended to use top and bottom protective nonwovens. In the event that the constructor uses other protective measures due to special stresses, in special cases the slide film can be delivered in the form of an unlaminated TG 1 A or laminated on one side TG 1 A + b3.

| Type | The maximum stress |

The friction coefficient |

The temperature | The thickness |

| N/mm2 | °C | mm | ||

| The slide film TG 1 A + b3 | 0,5 N/mm2 | 0,05 to 0,15 | 23 | 3 |

| The slide film TG 1 A + c3 | 0,5 N/mm2 | 0,05 to 0,15 | 23 | 5 |

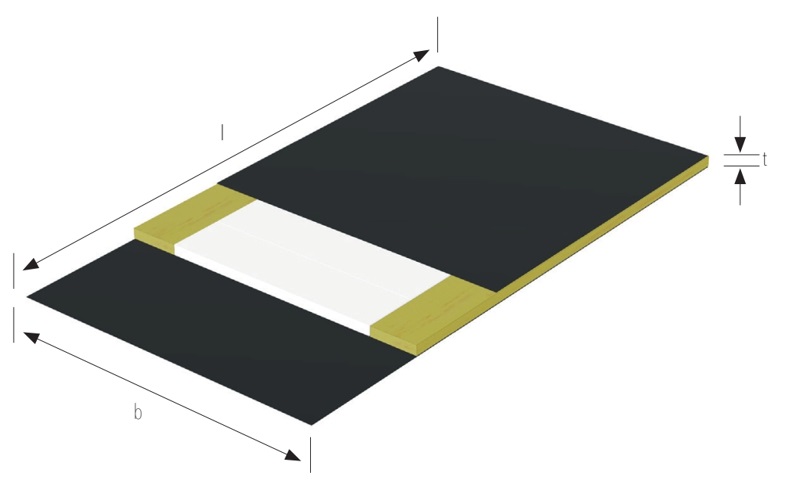

The standard length: up to 25 m

The width: 1 m standardly

Specification : t x b x l mm RUBA TG1A+ c3 type

t - the slide film thickness, mm,

b - the slide film width, mm,

l - the slide film length, mm.