Product description

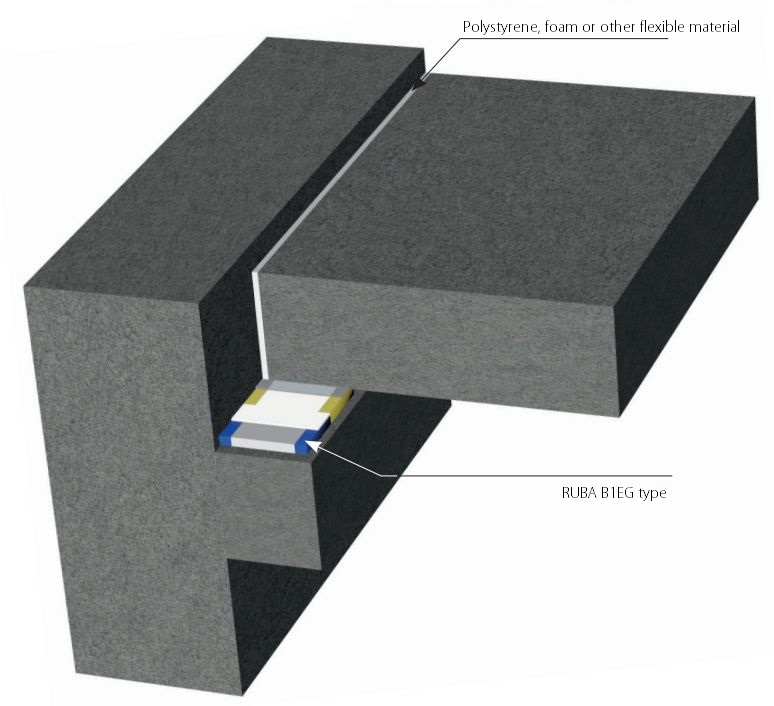

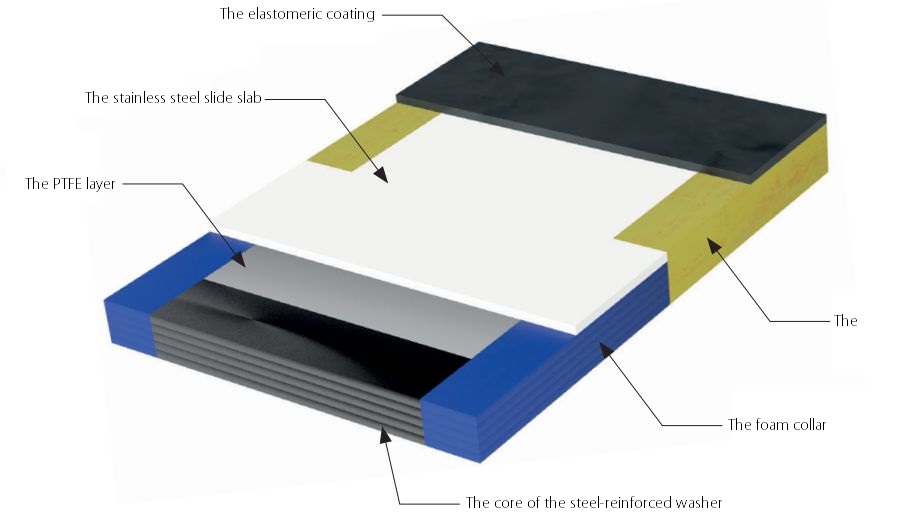

Point washers are designed for applications with a greater range of displacements with a pressure up to 15 N/mm2 The perfect selection of slide materials allows to minimize the friction coefficient while ensuring the proper bearing. The structure and material of reinforced slide elastomeric washers correspond to the structure and material of reinforced elastomer washers according to DIN 4141, part 14/140 or EN 1337-3. Permissible low values of vertical loads and rotation angles translate into a high level of safety for bearing of 1 class in accordance with DIN 4141, part 3, and are the result of decades of experience in their application in advanced bridge designs. Washers compensate for horizontal displacements by freely sliding the slide slab over the washer core. At the same time, they ensure that the load is transferred in a controlled manner, they even out the rotation on supports, and also compensate for unevenness and deviations of the support surface and the supported element.

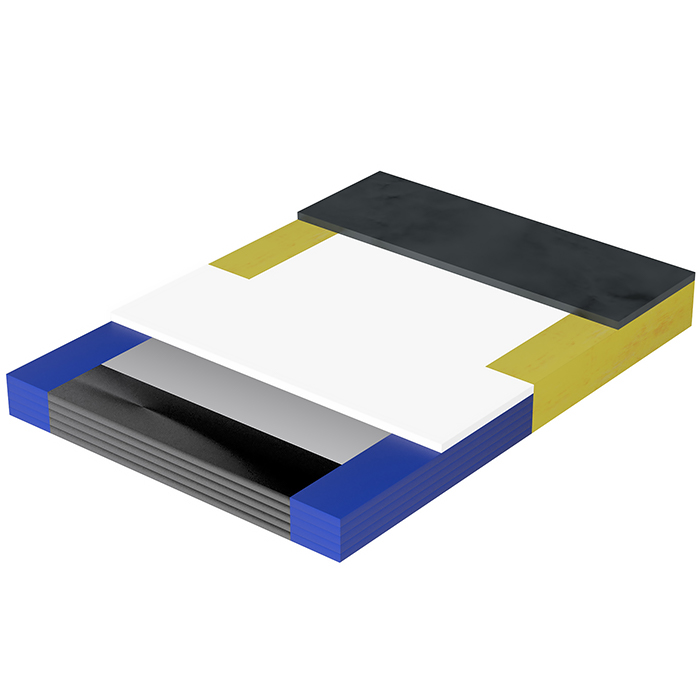

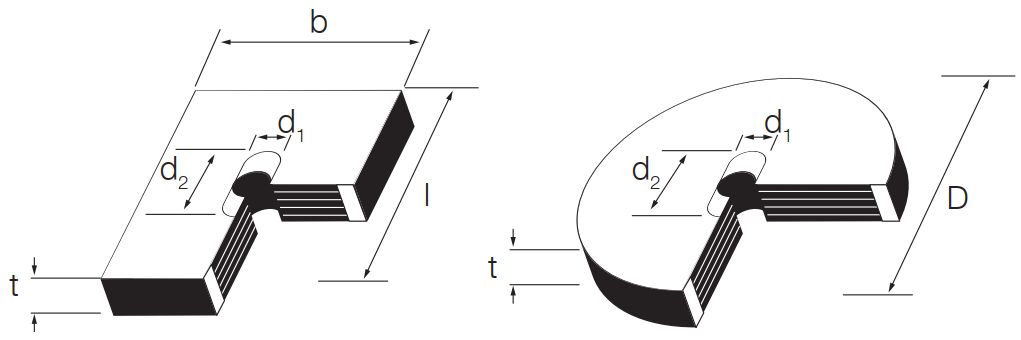

Washer's construction

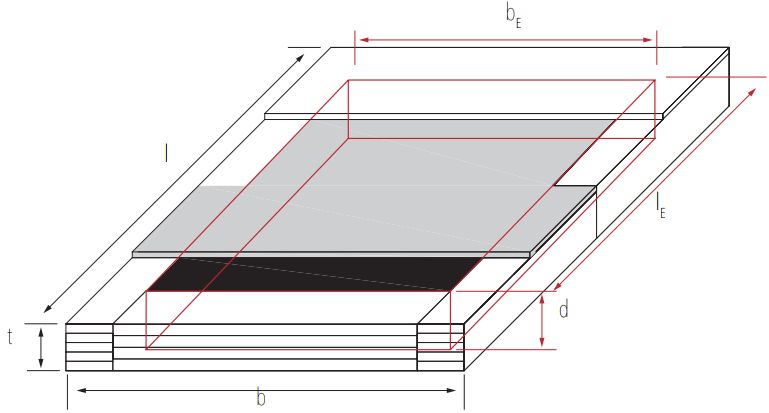

bE - the width of the elastomeric core, mm,

lE - the length of the elastomeric core, mm,

d - the thickness of the elastomeric core, mm,

b - the slide washer width, mm,

l - the slide washer length, mm,

t - the washer thickness, mm.

The friction coefficient 0.01 do 0.05 at 23 °C. The standard displacement range: ± 20 mm.

The permissible loads and rotation values can be found in the design table on page 14. Other dimensions, displacement ranges and anchor washers (e.g.. B2EG or B5EG) are available on request.

Specification: bE x lE x d / b x l / t mm RUBA B1EG type

Designation:

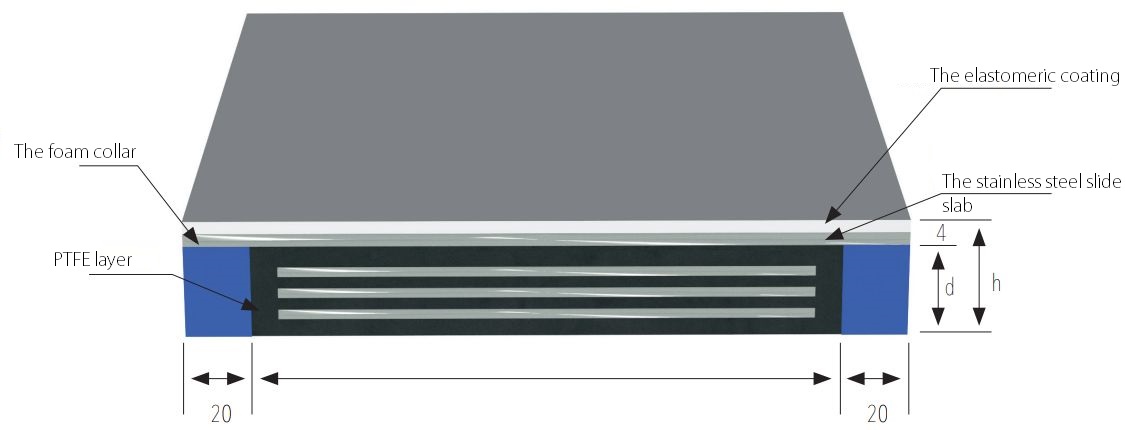

t - washer thickness, mm,

d - the thickness of the reinforced elastomeric core, mm,

b - the washer width, mm,

l - the washer length, mm,

a1 - the washer length, mm,

a2 - the length of the oval hole in the slide slab, mm,

D - the washer diameter, mm.

Dimension:

B1EG type washers are manufactured in any sizes. Theminimum size of the elastomeric core is 100 x 100 mm

| Washer dimensions |

The high of the elastomeric block |

The heigh of elastomer, d | The permissible torsion angle, F | The permissible torsion angle | ||||

| The washer core |

The standard slide slab |

The total height, h |

The shorter |

The longer side |

The permissible average lod of the washer |

|||

| mm | mm | mm | mm | mm | kN | ‰ | ‰ | mm |

| 100 x 100 | 140 x 140 | 14 | 10 | 8 | 150 | 4 | 4 | 15 |

| 18 | 14 | 10 | 4 | 4 | ||||

| 25 | 21 | 15 | 8 | 8 | ||||

| 32 | 28 | 20 | 12 | 12 | ||||

| 100 x 150 | 140 x 190 | 14 | 10 | 8 | 225 | 4 | 3 | |

| 18 | 14 | 10 | 4 | 3 | ||||

| 25 | 21 | 15 | 8 | 6 | ||||

| 32 | 28 | 20 | 12 | 9 | ||||

| 150 x 200 | 190 x 240 | 14 | 10 | 8 | 450 | 3 | 3 | |

| 18 | 14 | 10 | 3 | 3 | ||||

| 25 | 21 | 15 | 6 | 6 | ||||

| 32 | 28 | 20 | 9 | 9 | ||||

| 39 | 35 | 25 | 12 | 12 | ||||

| 200 x 250 | 240 x 290 | 14 | 10 | 8 | 750 | 3 | 3 | |

| 23 | 19 | 13 | 3 | 3 | ||||

| 34 | 30 | 21 | 6 | 5 | ||||

| 45 | 41 | 29 | 9 | 8 | ||||

| 200 x 300 | 240 x 340 | 14 | 10 | 8 | 900 | 3 | 2 | |

| 23 | 19 | 13 | 3 | 2 | ||||

| 34 | 30 | 21 | 6 | 4 | ||||

| 45 | 41 | 29 | 9 | 6 | ||||

| 250 x 300 | 290 x 340 | 14 | 10 | 8 | 1125 | 2 | 2 | |

| 23 | 19 | 13 | 3 | 2 | ||||

| 34 | 30 | 21 | 5 | 4 | ||||

| 45 | 41 | 29 | 7 | 6 | ||||

| 200 x 400 | 240 x 440 | 14 | 10 | 8 | 1200 | 3 | 1 | |

| 23 | 19 | 13 | 3 | 1 | ||||

| 34 | 30 | 21 | 6 | 2 | ||||

| 45 | 41 | 29 | 9 | 4 | ||||

| 250 x 400 | 290 x 440 | 14 | 10 | 8 | 1500 | 3 | 1 | |

| 23 | 19 | 13 | 3 | 1 | ||||

| 34 | 30 | 21 | 5 | 2 | ||||

| 45 | 41 | 29 | 7 | 4 | ||||

| 56 | 52 | 37 | 10 | 5 | ||||

| 300 x 400 | 340 x 440 | 14 | 10 | 8 | 1800 | 2 | 1 | |

| 23 | 19 | 13 | 2 | 1 | ||||

| 34 | 30 | 21 | 4 | 2 | ||||

| 45 | 41 | 29 | 6 | 4 | ||||

| 56 | 52 | 37 | 8 | 5 | ||||

| The standard range of the displacement: +/- 20 mm | ||||||||

| Other sizes are avilible on request. | ||||||||

Fire resistance

NEG washers have fire tests carried out in the Fire Research Laboratory of ITB (Laboratorium Badań Ogniowych ITB).

They have the REI 120 fire resistance class.

When selecting washers, the guidelines contained in the Technical Assessment No. 01155/17/Z00NZP should be taken into account.