Use

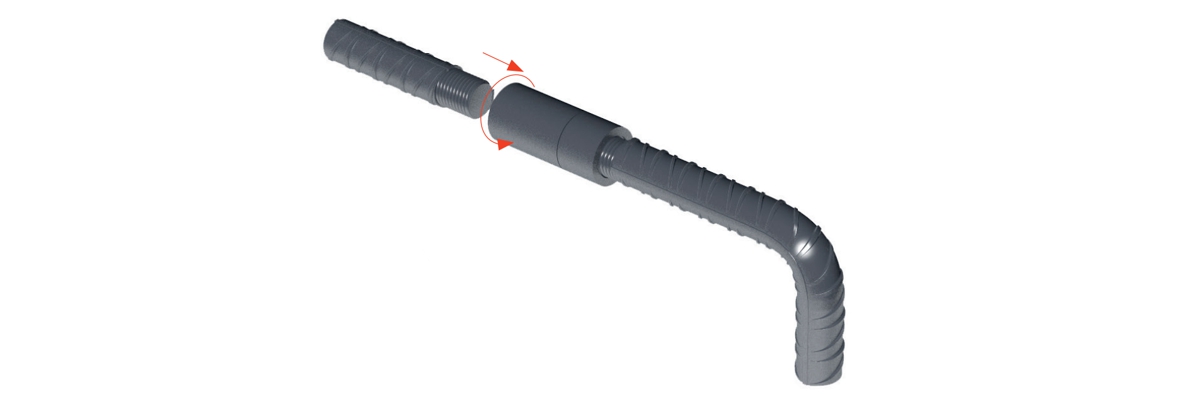

We use it when the connected element cannot rotate and locking the bar position is required. This method is similar to the previous one, with the difference that here we additionally use a locknut, which stabilizes the position of the attached bar.

1. At the end of the bar to be attached prepare a special section of the thread that allows the locknut of the standard sleeve to be screwed on until it is flush with the bar face.

2. Then we slide the bar connected to the base bar.

3. Screw in the sleeve until resistance is felt and stabilize it by tightening the locknut.

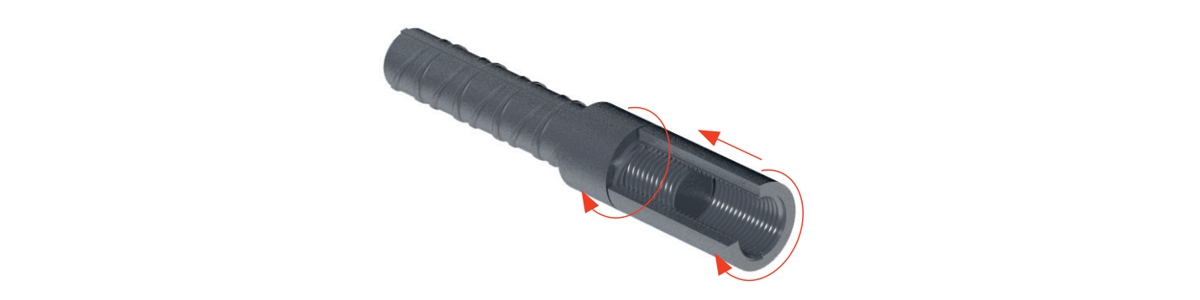

It enables smooth adjustment of the distance between ends of bars, which allows for the elimination of potential assembly inaccuracies. The maximum distance between bars may be one thread diameter.

1. At the end of the bar to be attached, prepare a special section of the thread that allows the locknut of the spacer to be screwed on until it is flush with the bar face.

2. Slide the connected bar to the base bar and screw the spacer to obtain the required position.

3. Stabilize the whole by tightening the locknut.

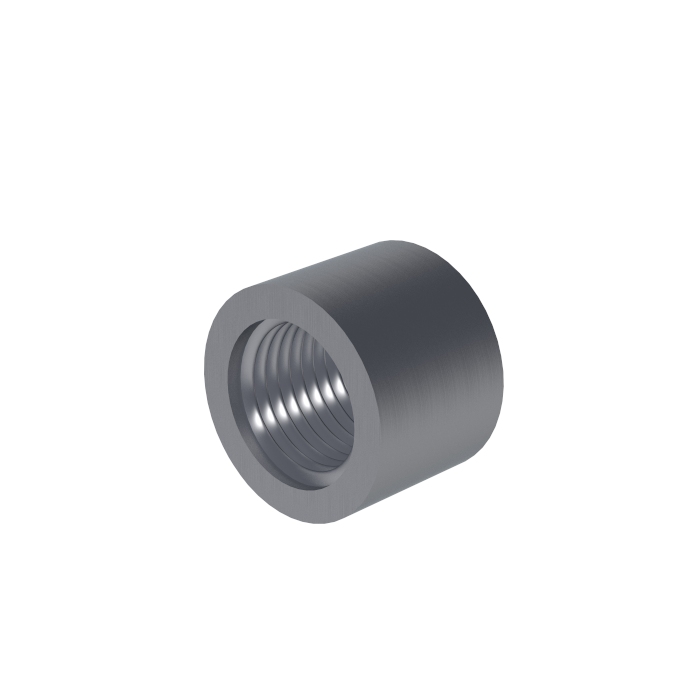

Assortment

| Art. no. | Designation | Thread | Ext. dia., D | Lenght, L |

| mm | mm | mm | ||

| 30301 | EN12 | M14x2.0 | 20 | 10 |

| 30302 | EN14 | M16x2.0 | 24 | 12 |

| 30303 | EN16 | M20x2.5 | 28 | 13 |

| 30304 | EN18 | M22x2.5 | 32 | 15 |

| 30305 | EN20 | M24x3.0 | 35 | 16 |

| 30306 | EN22 | M27x3.0 | 36 | 18 |

| 30307 | EN25 | M30x3.5 | 42 | 20 |

| 30308 | EN28 | M33x3.5 | 48 | 22 |

| 30309 | EN32 | M36x4.0 | 52 | 24 |

| 30310 | EN36 | M42x4.5 | 60 | 22.5 |

| 30311 | EN40 | M45x4.5 | 65 | 22.5 |